Sep26

Robert Bas place at your service/ disposal a spray unit made up of a spraying cupboard and a solutions’ making skid, with a practical and intuitive PROFACE touchscreen interface.

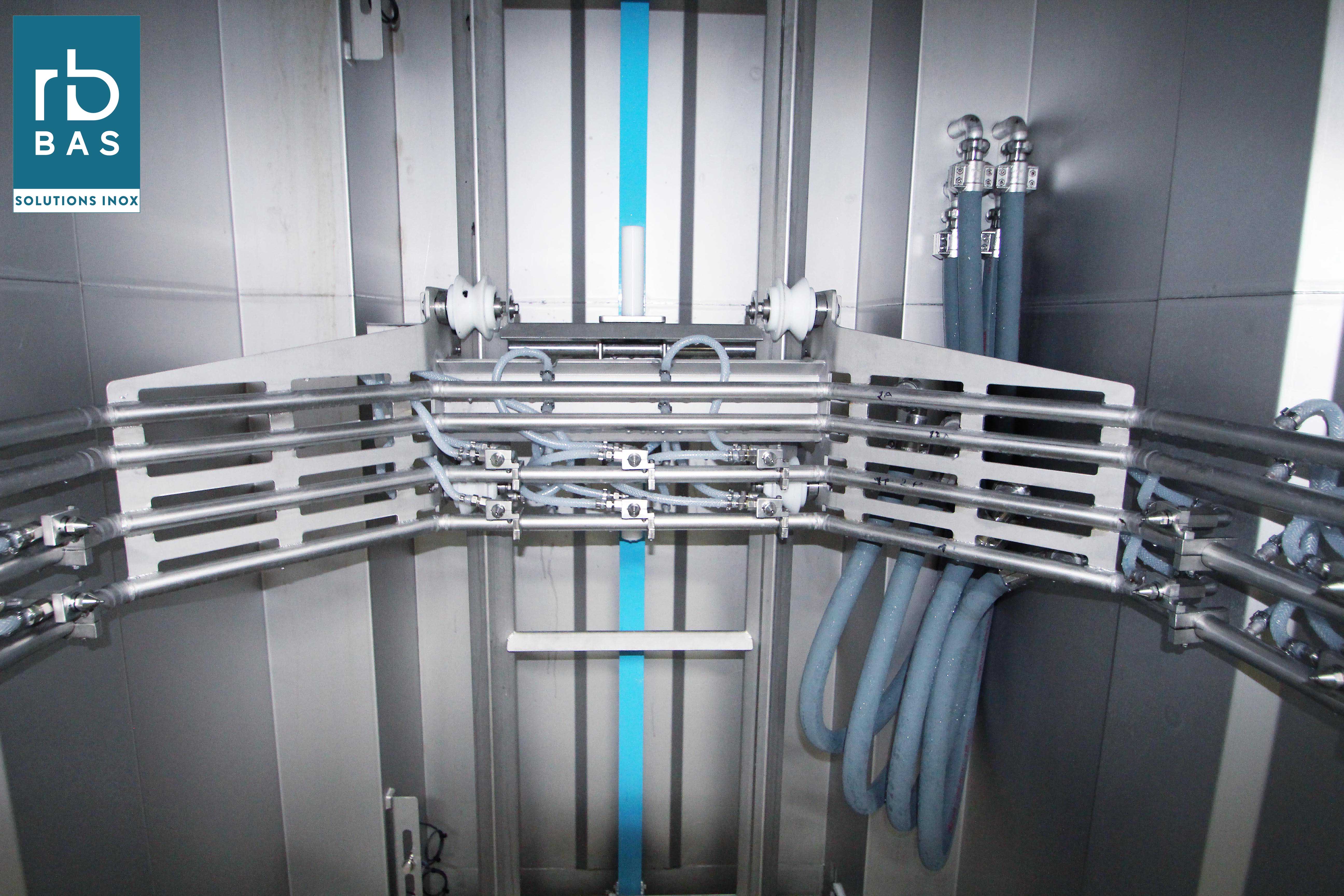

A double ramp forwards the food compressed air and the product to disseminate. The mixture air and product is made in the pneumatic mister. This combination allows to save up to 20% of product for the same application. It is possible to vaporize until 6L/min for a partial or total cover of the products. The air used for the vaporization is a filtered food compressed air thanks to a prefilter, a submicrofilter and an active carbon filter.

The solutions’ making skid, of a capacity from 25L to 100L, is used to blend, either by bubbling or by mechanical stirring.

For 28 years, Robert Bas has commited with its clients by offering stainless steel solutions to meet the agri-food, pharmaceutical and cosmetic industry needs. Thanks to its 35 employees, the company has acquired considerable technical expertise. Based on the mastery of the historical business and its 4 500 m² workshop, Robert Bas‘ team integrates stainless steel process systems and custom-made equipment throughout France and internationally.