Jun26

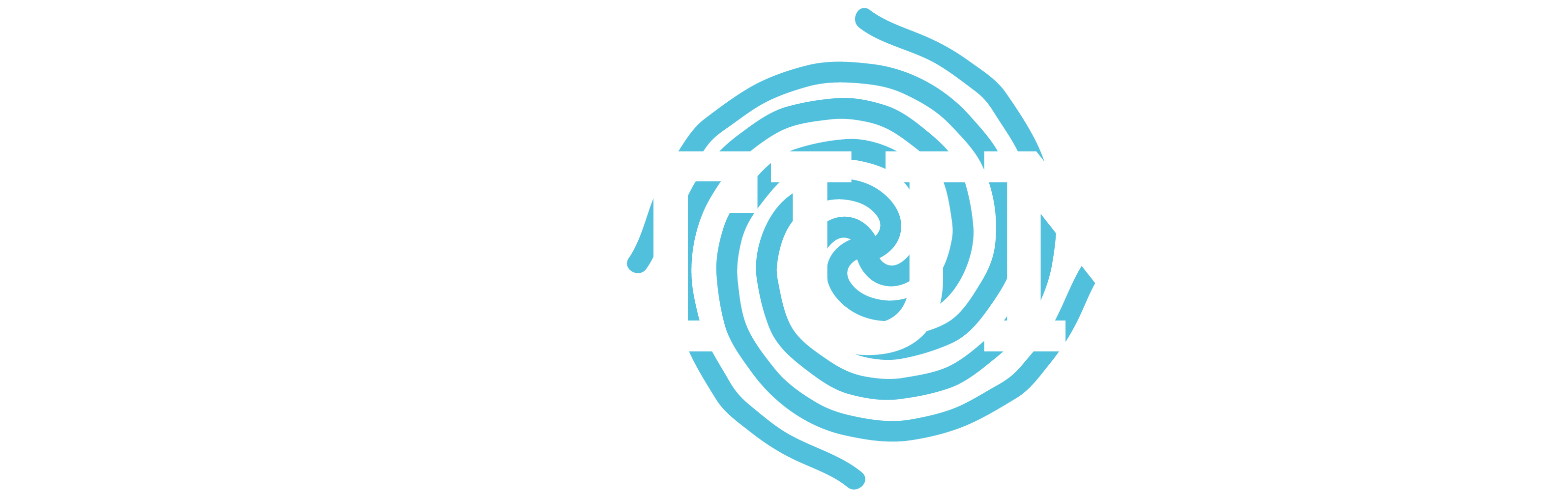

Introducing the new vision of this equipment : NEPTUNE ® a range of compact size CIP stations, readymade and accessible on a catalogue (standard + options) that fulfils most of your needs.

A client asks us to design a 4×2000 L CIP station equiped with 1 transfer line and 3 main requirements : ready to ship, easy to set up, completely autonomous. This client confirm his satisfaction by three other orders.

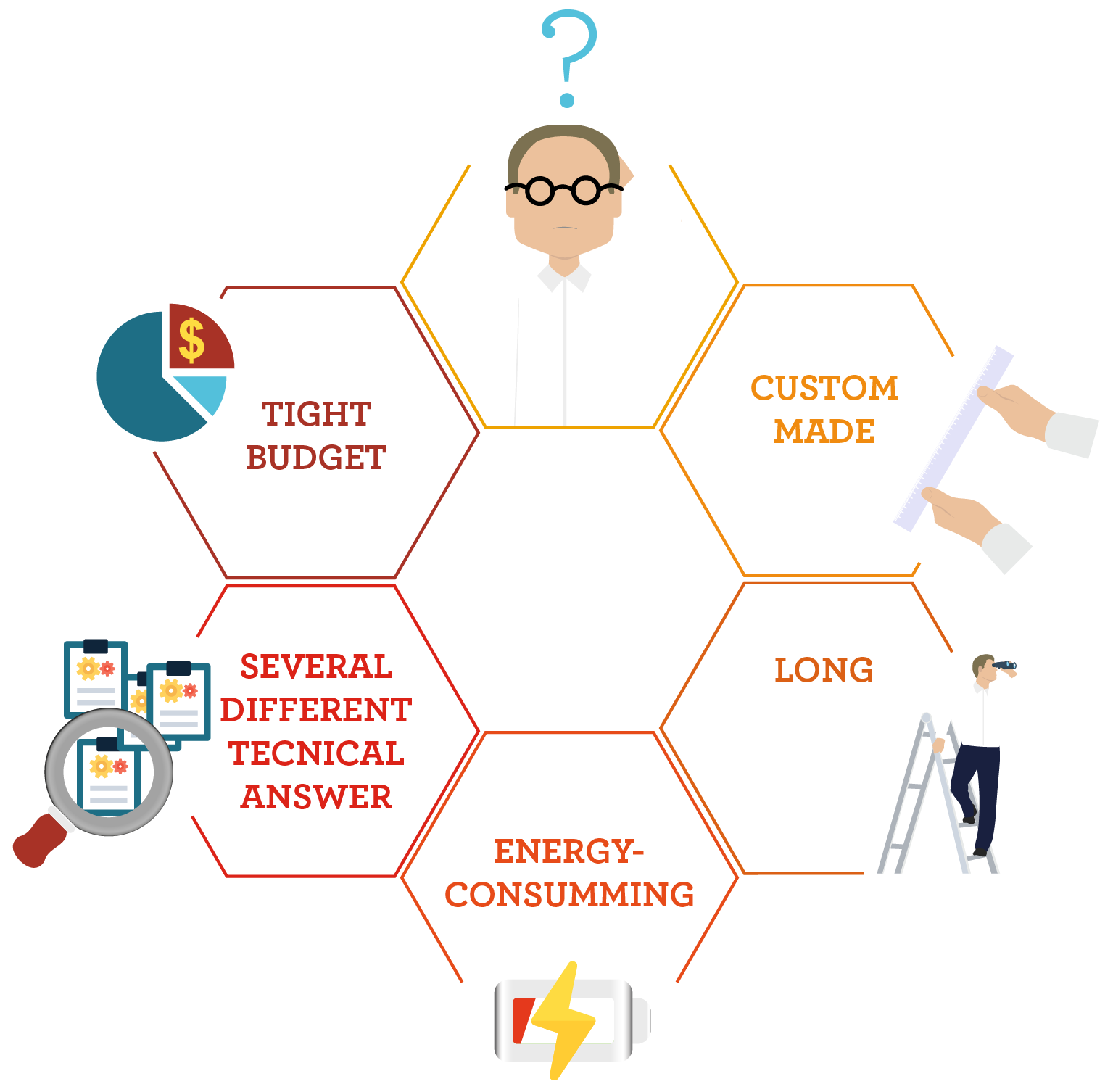

Based on this observation, we decide to create a project team and to make a market study.

The sum up of this study showed us the need to go back to fundamentals, wich is to offer a CIP station matching efficiently the basic function : cleaning according to the TACT.

We also note that no one on the market offers a standard CIP station. Even though the standard implies limited choices, it is essentially a homogeneous equipment, cheaper than the custom-made and available in a short time.

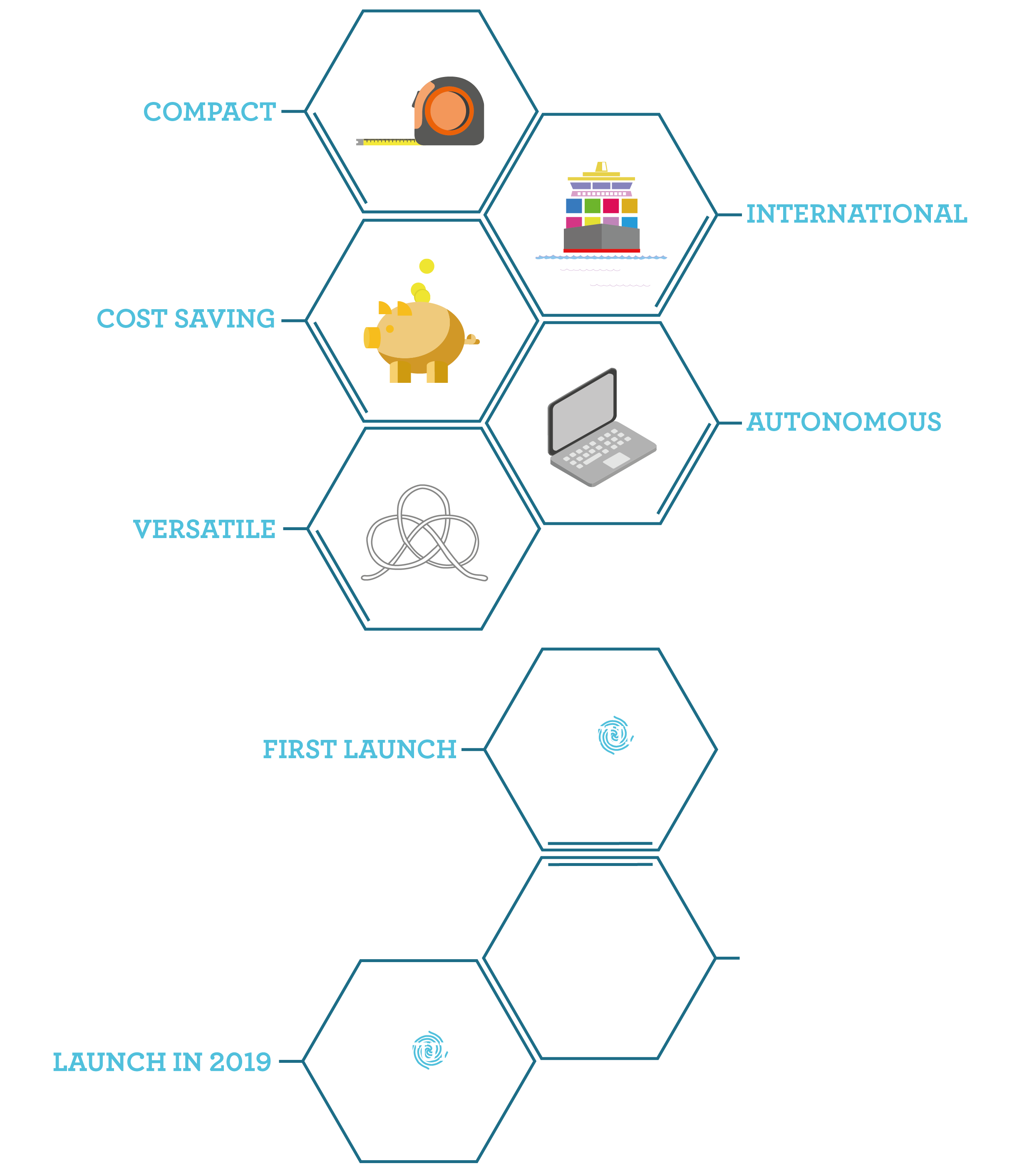

We unveil in March the first standard NEPTUNE ® 4-2000-1-20, a basic product at a controlled price. The customer can upgrade according to his needs, within the limits of the options defined.

The NEPTUNE ® 4-5000-1-30 will be marketed at the beginning of the year.

Running water consumption is calculated thanks to the flowmeter on customer’s new water supply.

The power supply is provide for in three-phase 25A and the compressed air between 4 to 6 bars of pressure.

Flow rate customizable thanks to the centrifugal pump on a frequency inverter.

Option : modification of the pump.

Cleaning media’s heating is made with direct steam injection in the pipes which, thanks to the circulation loop, allows to warm in line and in masked time.

Option : heating through plate exchanger.

The conditioning is made while the station is still, it is always ready to use.

The cleaning media refilling is automatic, by injection in the pipes to enhence their mixing.

Concentration checking is made after refilling.

Validation of the respect of the instructions of qualification of the cleaning thanks to the probes on the sending and the return. They allow a continuous reading.

Temperature regulation on the sending thanks to steam flow regulation.

Media temperature check thanks to other sensors on alkaline and acid sections.

Temperature extra is ade in the loop, in line and when sending.

Options :

– self-rinsing : asic rinsing with spray balls conected to new water circuit.

– self-cleaning : loops of alkaline and acid in every sections, with a final rinsing with new water.

For these two options, sections are equipped with otary spray balls.

High safety level thanks to presure probes and level probes. They warm is case of problem and prevent the pumps from running dry.

Real time level détection in each section.

Automatic clogging detection on the filter, to avoid clogging and alert operator.

Option : self rinsing of filter.

Checking valves position (manual mode) thanks to position probes.

3 modes :

– automatic : launching customized recipes (shadow time preparation) ;

– manual : accessible only with password, allow to maintain equipment or force some functions ;

– onward march : to force manually the conditionning.

Fault recording is limited on standard version.

Option : tracability and complete saving of cycles on USB key.

Bang-bang control :

– 15 recipes ;

– fault ;

– recipe’s start.

PLC informations table at disposal via Ethernet allows to transfer more information such as : conductivity, flow rates, temperatures, levels …

NEPTUNE ® CIP cleaning station is design to be compatible with the most demanding CIP analisis sofware, of which «CIP ANYWHERE» which allows traceability, safety and optimisation of cleaning.

En partenariat avec :

For 28 years, Robert Bas has commited with its clients by offering stainless steel solutions to meet the agri-food, pharmaceutical and cosmetic industry needs. Thanks to its 35 employees, the company has acquired considerable technical expertise. Based on the mastery of the historical business and its 4 500 m² workshop, Robert Bas‘ team integrates stainless steel process systems and custom-made equipment throughout France and internationally.